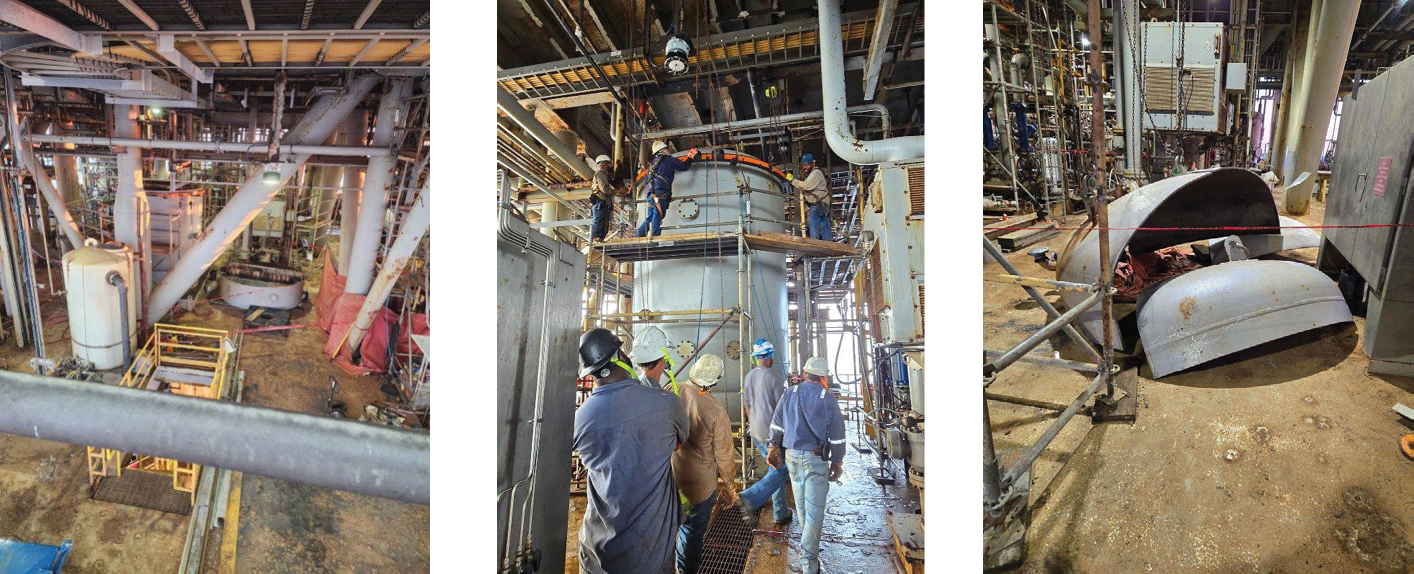

Old Floatcell Removed via Cold Cutting & Bull Rigging

120” Vessel Cuts, No Crane Access

A client was removing the existing vessel to replace with a smaller and more efficient vessel. BlueFin was called to make four (4) cold cuts at different locations on the vessel for ease of removal. The vessel was located beneath an overhead deck, and about eighty (80) feet away from the handrail, which didn’t allow for crane access.

Location

Gulf of America

Scope

Make four (4) cold cuts at different locations on the vessel for ease of removal.

Specifications

120” OD x 1.00” WT

Challenges

Vessel was located beneath an overhead deck, and about eighty (80) feet away from the handrail, which didn’t allow for crane access.

Solutions

Bull rigged all equipment and materials to and from the vessel.

Plan of Execution

The cold cutting equipment was bull rigged across the deck to the vessel. It was then bull rigged into position on the vessel. Four (4) cuts were completed along the height of the vessel. Each section of the vessel was lowered to the deck as the cuts were completed.

The cut sections of the vessel then had to be cut into smaller pieces and bull rigged across the deck to crane access. Once all cutting activities were completed, the cold cutting equipment was then bull rigged across the deck for crane access.

Technical Achievements & Benefits

Despite weather delays, the project was completed on schedule.

The added challenge with having to bull rig all equipment and materials across the deck, was executed without incident.