Well Integrity: A Holistic Approach To Annulus Pressure Management For Subsea Wells

WHAT IS ANNULUS PRESSURE MANAGEMENT AND WHY IS IT IMPORTANT?

Annulus Pressure Management refers to an engineered approach ensuring that casing annulus pressures do not challenge the well’s integrity during the life of the well. The aim is to maintain the casing pressure within the well’s mechanical design limits at all times by controlling the ‘A’ annulus pressure.

The ‘A’ annulus is the annular space between the production tubing and the first string of casing (i.e. production casing) as shown in Figure 1. In subsea wells, the ‘A’ annulus is the only annulus that can be monitored and controlled.

The ‘A’ annulus is monitored via a pressure transducer located on the subsea tree which is linked to the control system. As shown in Figure 1, subsea wells are typically designed with an Annulus Monitoring Line via a subsea distribution system and an umbilical system that are tied back to the host facility (typically referred to as an Annulus Monitoring, AMON, or Auxiliary System).

Managing the ‘A’ annulus pressure is critical in order to ensure the integrity of the well, as it is the only means to adjust pressure. Operating the ‘A’ annulus outside of its allowable operating envelope may result in a tubing, casing, or downhole equipment failure, which could have catastrophic consequences. As a result, well integrity is a key area of focus with industry regulators.

REGULATORY REQUIREMENTS FOR SUBSEA WELLS

The following regulatory requirements pertaining to well integrity are currently in place and enforced by the Bureau of Safety and Environmental Enforcement (BSEE) for offshore wells in the United States.

30CFR 250.517 requires that subsea wells be equipped with the capability to monitor the production casing annulus (i.e. ‘A’ annulus). Note: As opposed to fixed platform wells (or ‘dry trees’) that must be able to monitor all annuli (A, B, C, D, etc., annuli).

30CFR 250.518 requires that API RP 90 casing pressure management requirements must be met; however, this CFR takes precedence should a conflict between both arise.

30CFR 250.519 requires that annulus pressure must be monitored continuously for subsea wells and with a minimum of one pressure data point recorded per day.

NTL No. 2009 – G22 encourages the use of API RP 90, Annular Casing Pressure Management for Offshore Wells, as guidance for evaluating casing pressure and for testing methods and collection of data. This NTL clarifies the practice of venting casing pressure during initial well startup, and, in addition, it establishes how the Maximum Allowable Wellhead Operating Pressure (MAWOP) for the ‘A’ annulus is to be determined. As per API RP 90, the wellhead MAWOP is the lesser of:

50 percent of the minimum internal yield pressure (MIYP) of the pipe body for the casing or production riser string being evaluated (i.e. Production Casing)

80 percent of the MIYP of the pipe body of the next outer casing or production riser string (i.e. Intermediate or Surface Casing)

75 percent of the minimum collapse pressure (MCP) of the inner tubular pipe body (i.e. Production Tubing)

Note: MAWOP is a measure of how much pressure can be safely applied to an annulus and is applicable to all types of annular pressures, including thermal casing pressure, Sustained Casing Pressure (SCP), and operator-imposed pressure. The MAWOP is measured relative to the ambient pressure at the wellhead for any selected annulus.

ANNULAR PRESSURE BUILDUP (APB)

The term Annular Pressure Buildup (APB) refers to the thermal phenomenon present, to some degree, in all producing wells and is the main driver for Annulus Pressure Management. Land well operators have known for many years that annular pressure will build as new wells are brought on production.

Annular pressure is generated when annular fluids are heated by production and expand. Pressure is relieved by opening the casing valve and venting the pressure to a tank or flowline. In many onshore and shallow water wells, it is common practice to overlap a previous casing shoe with cement. Thus, the annulus above becomes sealed (i.e. trapped) as shown in Figure 1.

Deepwater wells, with subsea wellhead housings, have no means to bleed APB pressures outside of the ‘A’ annulus, due to the seal section present in all casing hanger assemblies (with the exception of the ‘A’ annulus). When the annulus is sealed, with no means for the fluid to vent, substantial pressure can result creating a burst load on the outer casing and a collapse load on the inner casing. Analysis shows that annular pressure in deepwater wells can approach 15,000 psi given the right conditions. The magnitude of such pressures demands that the casing design and necessary mitigation strategies be carefully evaluated during the design process. After the well is drilled it may be too late to employ the most cost-effective mitigation technique. Future GATEKEEPERs will go into more detail on APB mitigation design techniques.

ANNULAR PRESSURE BUILDUP THEORY

The fundamental theory for APB from thermal effects is as follows:

When an unconstrained fluid is heated, it will expand to a larger volume as defined in Equation 1:

If the fluid is constrained by a perfectly rigid container, the pressure increase is calculated as shown in Equation 2

By substituting Equation 1 into Equation 2, Equation 3 shows that the pressure increase is a function of the fluid properties and the average temperature change for a simple rigid container:

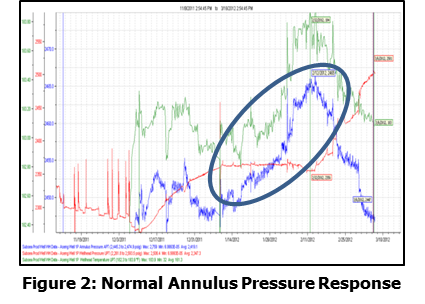

The Figures 2 and 3 represent a recent case study during an initial well start-up. Figure 2 shows a normal annulus pressure response. Figure 3 shows a well’s annulus pressure response indicating a tubing/casing leak.

ANNULAR PRESSURE MANAGEMENT CONTROL MECHANISMS & INTERFACES

In addition to thermal effects, annular pressure change may be driven by:

Downhole gas lift operations for production optimization (i.e. gas lift via ‘A’ annulus)

Pressure leakage through the completion hardware such as the production packers

Pressure leakage through the production tubing or casing string

Leakage through the crossover valves in the subsea tree

Leakage from an HP or LP hydraulic line

Leakage from a downhole chemical injection line

Wellhead or tubing hanger leakage

Ballooning

The ‘A’ annulus pressure may be controlled via the following methods:

Annulus venting into subsea production flowline via tree crossover(s) valves (i.e. Direct Venting Method) – See Figure 4 for an example

Annulus bleed down via umbilical tube to topsides facility (via AMON or AUX system)

Annulus pressurizing via umbilical tube from topsides facility (via AMON or AUX system). Note: Typically, the subsea control system (or MCS) contains alarms and/or shutdown sequences programmed for protection of the ‘A’ annulus pressures.

Other design mitigation techniques which will be discussed in subsequent GATEKEEPERS.

Annulus Pressure Management involves many disciplines and scopes including:

Well Engineering, Drilling and Completions

Reservoir and Production Engineering

Flow Assurance

Topsides and Subsea System Design

Initial Startup and Operations

BRINGING IT ALL TOGETHER

The philosophy of GATE & Viking Engineering is to couple the well design aspects with the rest of the system (i.e. linking the system below mudline with the system above the mudline). This includes linking transient thermal-hydraulic modeling in order to provide a more complete solution to annulus pressure management and initial startup APB predictions.

These results are then coupled with the initial startup procedures and flow assurance modeling. For example, an initial startup APB analysis may predict that the well will be required to be shut-in 4 hours after the initial well startup as per the well’s ramp-up schedule, in order for the casing to be bled down. This may have a significant flow assurance risk and hence must be considered and incorporated into the overall initial startup plan and procedures.

Adequately capturing and incorporating ‘A’ annulus pressure operating envelopes and annulus pressure management into standard operating procedures, and adequately training operators, is critical to success. See Figure 4 for an example of a typical annulus operating window.