Torque & Drag

Protect your casing investment by knowing your torque and drag loads. We deliver analysis and easy operational visuals.

Our Services

Easy Operational Visuals

Torque & Drag Modeling

Side-force Modeling

Connection Selection

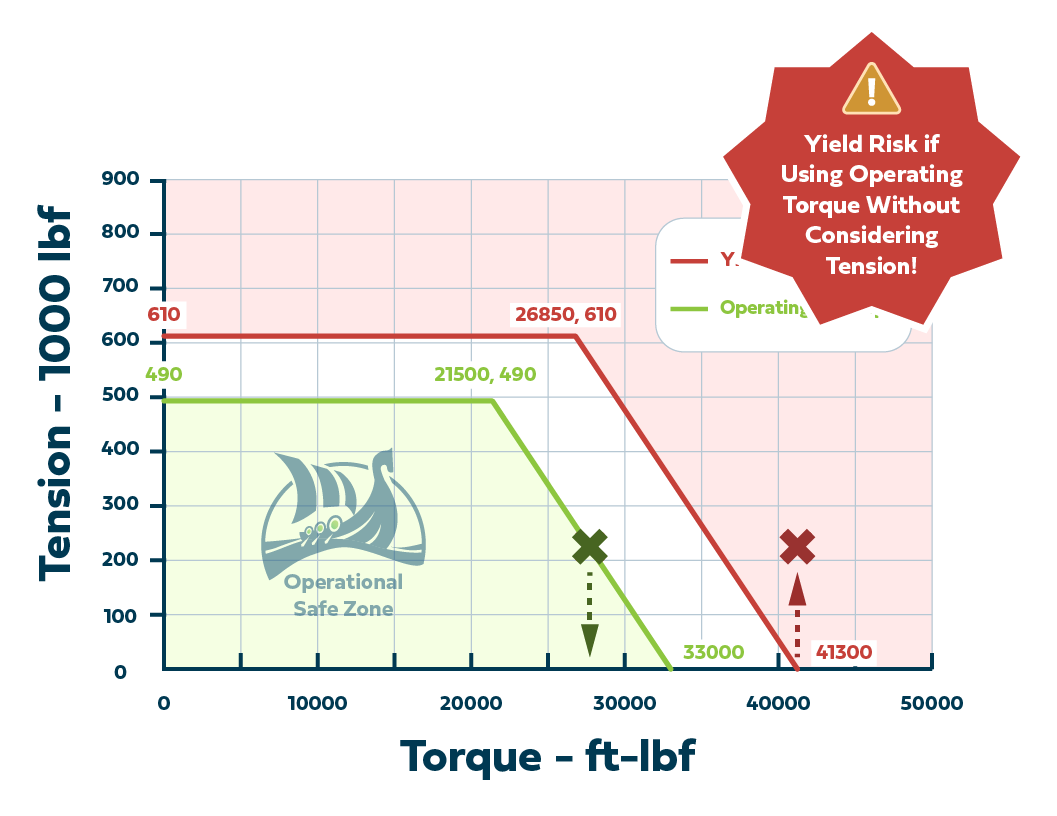

Torque–Tension Operating Envelope

Casing Flotation Planning

Recommendations for Casing Run / SOP

Minimum Rig Requirements

Field Operations Support

90%

OF FAILURES ARE DUE TO CONNECTION ISSUES

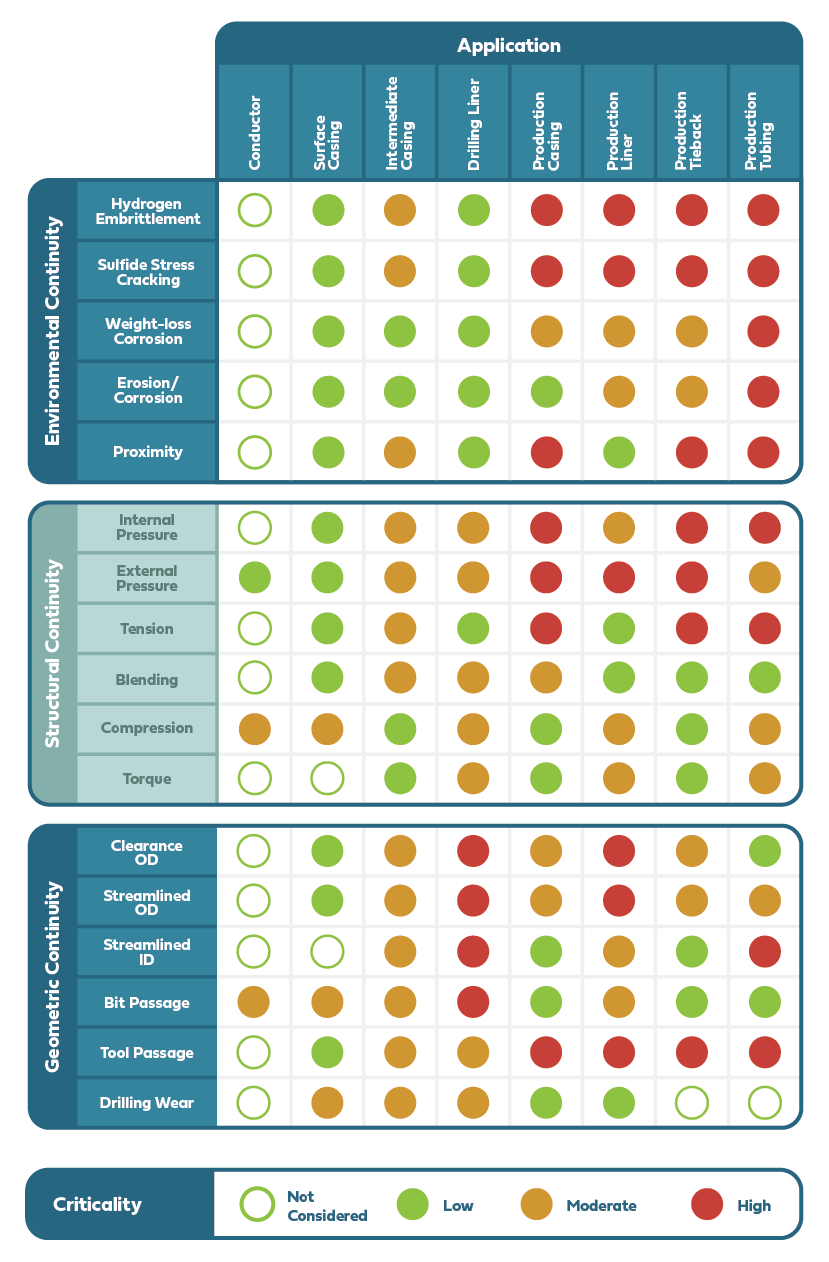

Proper selection of a connection should be based on the required performance properties, not just price.

We Deliver Analysis & Easy Operational Visuals

We analyze the specific environment of every string—recognizing that the service demands of the surface casing differ vastly from the demands of floatation and rotation of the production casing.

Analysis we deliver:

Torque & Drag Modeling

Side-force Modeling

Connection Selection

Torque–Tension Operating Envelope

Casing Flotation Planning

Recommendations for Casing Run / SOP

Minimum Rig Requirements

Field Operations Support

Easy Operational Visuals

By knowing the operating limitations of the connection and what conditions to expect, you can rest easy at night knowing that your operational team will be able to install the casing run safely.

Why it Matters to You As an Operator

We prioritize performance properties over price, ensuring your well doesn’t fail where it matters most.

Our Priorities:

Keep Everyone on Your Team Safe

Confidently Run Long & Complex Strings

Match the Right Connection to the Realistic Torque and Drag Demands of Your Asset

Reduce NPT, Stuck Pipe Risk, & Costly Fishing or Sidetracks

Protect High‑value OCTG from Avoidable Damage & Extend Service Life

Give Your Crews Clear Limits Before Operations Start—Not After Something Fails